MILCO Wire EDM Services

Innovation Through Technology

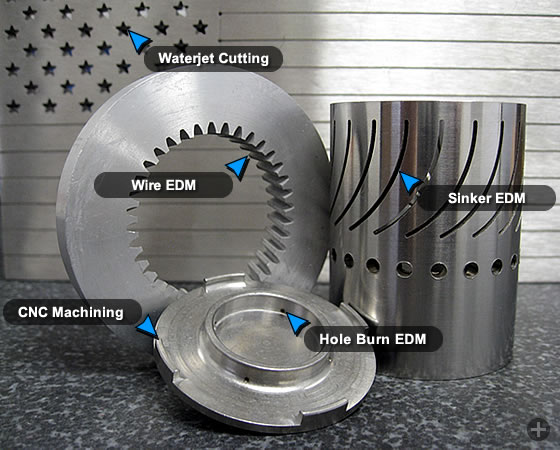

Mouse over capability types for description and corresponding page link

Precise, Reliable, Consistent, Affordable EDM Services

MILCO Wire EDM, an AS9100 Certified EDM services provider, offers top quality electrical discharge machining

services and has been the industry leader since 1990. With capabilities of Wire

EDM, Small Hole EDM Drilling, Conventional

/ Sinker EDM and Water-jet services. Catering to all aspects of manufacturing

industries, including: Medical, Surgical,

Aerospace, Missile,

Defense, Aeronautical,

Satellite, Tool

and Die, Stamping, & Commercial. MILCO Wire EDM has been far exceeding customers'

and clients' standards, we hold a reputation of the fastest turnaround

and highly competitive pricing. We here at

MILCO have a highly trained and skillfully

dedicated staff, who strive to make every effort

possible to surpass and exceed our customers'

expectations. Call us today for a free estimate

and quotation. Send us an email or fax us your

prints, drawings, files or questions so we

can help your ideas or products come to life!

High Quality EDM Cutting & Prototyping

Achieving high accuracy and tighter tolerances is essential for many industries such

as aerospace, medical, injection molding and tool and die. With Electrical Discharge

Machining we can produce and repeat the required specifications with ease. Contact

MILCO Wire EDM for all of your electrical discharge machining needs including,

EDM drilling machines, Small Hole drilling machines, Sinker machines and Wire electrical

discharge machining.

Electrical Discharge Machining (EDM) Process Explained

Wire EDM, Sinker EDM and Small Hole EDM are the three fundamental pillars of EDM Machining. Each one is a unique process, utilizing a different type of machine, each with a different way in which the electrode and workpiece are engaged to produce a final result.

The Wire EDM method is the most widely used in volume and is commonly utilized to manufacture and produce numerous components for aerospace, medical and manufacturing industries. This includes but is not limited to; tool & die components, punches, tooling, splines, extrusion dies, air foils, turbine blade components, internal and external gears, keyways, slots, medical devices, instruments, and prototypes that are intricate in design with incredible tolerances held.

Electrical conductivity is the unifying requirement with all of these components. The material of the workpiece must be electrically conductive for the electrical discharge machining process to work. If not conductive, complications will arise to varying degrees from poor cycle times to incapability of production. Machining with optimal conditions will greatly increase the productivity and efficiency of the overall process, thus keeping part costs to a minimum, and repeatable conditions at a consistent rate.

A superior level of accuracy, tightened tolerances and an increased surface finish can be achieved through EDM that conventional machining methods cannot normally ascertain. Intricate details and a small kerf are also unique to EDM as small diameter wire can be used, that which would not be possible in traditional machining methods. This is due to the fact that the Wire EDM cutting process exerts no cutting force or tooling pressure onto the part. There is no residual stress caused and little changes in the mechanical and thermal properties of the target material are imposed.

Milco Postcard Download |

|

Milco Capability Summary

CLICK HERE TO DOWNLOAD A PDF VERSIONAS9100:D since 2010 |

AEROSPACE |

Year Est. 1990 |

CAGE CODE: 1XBS7 |

Non-conventional machining is vital to many companies and businesses throughout the United States, providing quality services to support a wide variety of industries.

|

|

WIRE EDM NA1200 15.74” x 11.80” Z=8.66 |

SMALL HOLE EDM CT500F 13.8” x 19.0” Z=12.0” SINKER EDM

EX8 11.80” x 9.90” Z=8.80” |

WATERJET 2) Omax machines 55” x 100” Z = 6.5’ |

PAST PERFORMANCES Wire EDM inside and outside periphery leaving .008” wall in 4 places (aerospace)

|

MACHINABLE METALS Metals of all Alloys, Brass,

Copper, Tool Steel,

Aluminum, Titanium,

Rubber, Stone, Ceramic, Plastics, Glass For health and safety reasons we will not accept any carcinogenic materials |

QUALITY INSPECTION INFO

Preventative maintenance and calibration on all machines.

|