Industries

Aerospace EDM

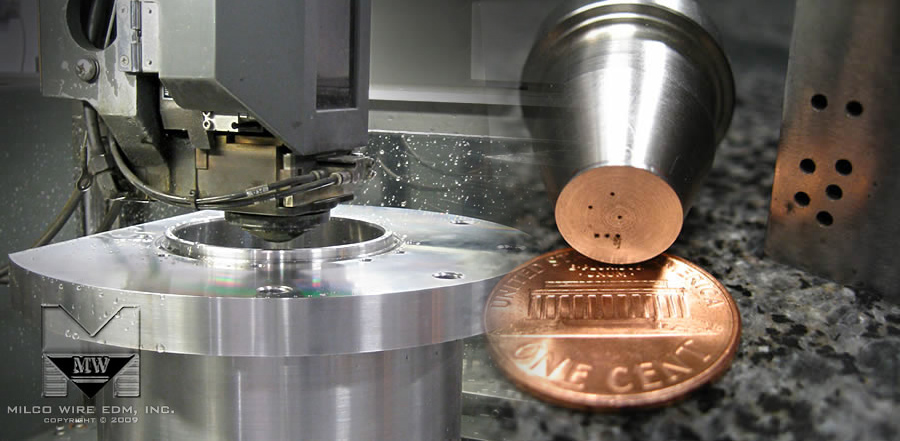

MILCO Wire EDM Specializes in providing Wire EDM, Sinker EDM and Small hole burning (Electrical Discharge Machining) Services to the Aerospace Industry.

We manufacture all sizes of production parts for aircraft, helicopter, jet and missile. From rocket guidance systems to unmanned flight hardware, to drone surveilance and gyroscopes MILCO has played a role in making tens of thousands products for our customers.

MILCO benefits the Aerospace Industry by using:

- Electrical discharge machining of high temperature alloys and exotic metals used for aerospace applications.

- High Volume and prototype order Production Capacity

- EDM Wire, Sinker, Ram and Fast Hole and Small Hole Popping

- 30% of our work is done for the Aerospace Industry

- Aerospace materials: Aluminum, Nickel, Titanium and Stainless Alloy

- Rare Aerospace materials such as Kovar, Invar, Inconel, Niobium, Scandium and much more

Medical EDM

MILCO's portfolio and catalogue of parts have ranged from the simple to the extremely complex. The categories of parts we have made are as broad as our expertise. Here's just a few of the items we have manufactured in our facility:

- Electrical discharge machining of high temperature alloys and exotic metals used for aerospace applications.

- Surgical screws, bolts and hardware.

- Medical implantation hand tools for inserting and extraction or recovery of implants.

- Surgical Cathodes and syringe components.

- Bone / Jaw reamers for Dental implants.

- Go / No Go Gauges for Medical inventory quality control.

- Breathing Regulator valves for oxygen masks.

- Various splints and supports for orthotic and prosthetic devices.

- Knee joint, shoulder joint and hip joint support apparatuses.

- Tooling and dies for manufacturing, and stamping medical equipment and tools.

Whether we are machining medical tweezers used on a surgical robot or wire edm machining custom forceps or hole-burning a flushing hole on a dental drill; we are always striving for more ways to satisfy the needs of our diverse customer's demands.

Communications EDM

MILCO Wire EDM has years of experience manufacturing numerous components for the communications industry, and is a leading contract manufacturer of communications parts and products for all aspects of the field including satellites, ground structures, telecommunications, and more.

MILCO Wire EDM is extremely proud to supply Wire EDM, Sinker EDM and Small hole burning services to a large number of firms operating globally to continuously improve upon our communications infrastructure. We understand that operating in the communications manufacturing market demands unrivaled accuracy, extreme precision, and the ability to rapidly accomodate the ever changing needs of the constant innovations happening in the communications sector.

Defense / Military EDM

MILCO is an approved vendor to a respected group of leading Aerospace & Defense Industry Manufacturers such as The Boeing Co. Boeing Phantom Works, & Boeing Integrated Defense Systems, General Dynamics, BAE Systems, Standard Armament, United Defense, U.S. Air Force, Parker Hannifin, Honeywell, Rockwell-Collins, Meggitt Defense Systems, Northrop Grumman, Lockheed Martin.

MILCO uses numerous resources in order to manufacture nearly everything, from simple parts to complex and highly intricate assemblies that are utilized on a variety of different applications. These defense components are made up of numerous and exotic materials such as: Titanium, Inconel, H480, H4100, Ar236, AR400, AR500, Niobium, Stainless Steel, Aluminum, Molybdenum, Kevlar, Bullet-proof Glass, Waspaloy, Hastelloy and many other exotics that fit your requirement.